Ever wondered how thick is the sidewall of a tire and why it matters? It might seem like a minor detail, but the thickness of a tire’s sidewall plays a crucial role in its performance, handling, and safety. Embark on a journey to unravel the secrets of tire sidewall thickness and discover its profound impact on your driving experience.

Understanding the thickness of a tire’s sidewall is crucial not only for vehicle performance but also for safety and durability. This essential component, often overlooked, profoundly influences how your vehicle interacts with the road. It’s about more than just how thick is the sidewall of a car tire; it’s about understanding their role in your driving experience.

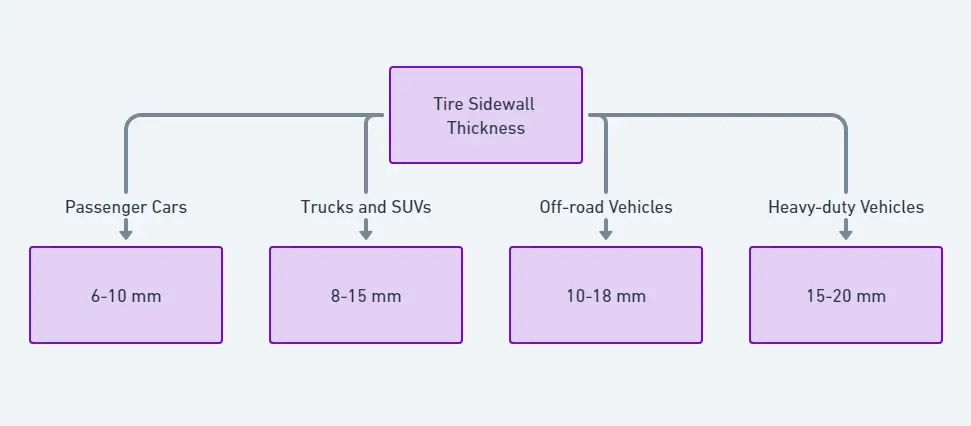

Tire sidewall thickness typically ranges from 0.24 to 0.60 inches (6 to 15 millimeters), depending on tire type and vehicle. Passenger car tires typically have 0.24-0.40 inch (6-10 mm) thick sidewalls. Light truck tires range from 0.32-0.60 inches (8-15 mm), SUV tires from 0.40-0.72 inches (10-18 mm), and heavy truck tires from 0.48-0.96 inches (12-24 mm).

Sidewalls in these range are critical in determining tire durability and tire safety, affecting how your vehicle handles bumps and maintains stability at high speeds.

In this exploration, we’ll delve into not just how thick are car tires, but also how this measurement forms the cornerstone of a safe and enjoyable driving experience. As we peel back the layers of the tire’s sidewall, we uncover the balance of engineering and design that contributes to our journeys’ safety and comfort.

What is a Tire Sidewall?

The tire sidewall is the part of the tire located between the tread and the bead, playing a pivotal role in the tire’s overall structure. It is not just a passive part of the tire but a key component in determining its performance and safety.

Made primarily from a specially formulated rubber composition, the sidewall is designed to withstand various stresses while providing flexibility and durability. This area of tire construction is crucial for protecting internal components from external damage and for supporting the weight of the vehicle.

It also plays a significant role in how the tire responds to road conditions, impacts, and cornering forces. The sidewall’s design and sidewall thickness directly influence the tire’s ride quality, handling characteristics, and overall lifespan.

Essentially, the sidewall is a multifunctional segment that balances protection, performance, and information dissemination, making it an integral part of tire sidewall construction.

Components of the Sidewall

A tire’s sidewall, an integral part of tire sidewall construction, is composed of various components, each serving distinct functions:

- Rubber Composition: This is the primary material of the sidewall, providing necessary flexibility and durability. The specific formulation of the rubber affects the tire’s ability to absorb shocks and impacts, playing a crucial role in the overall performance and safety of the tire.

- Ply Layers: These are the structural backbone of the sidewall, embedded within the rubber. The number of plies affects the sidewall thickness and, consequently, the tire’s strength and capacity to withstand external pressures and damage.

- Sidewall Stripe: Often overlooked, this decorative feature can be color-coded and serves as a brand differentiator, adding a visual appeal to the tire.

- Size Designation: A critical component, it includes alphanumeric codes that detail the tire’s width, aspect ratio, type of construction (like radial), and diameter. This information is essential for proper tire selection and usage.

- Load and Speed Ratings: These ratings, indicated by codes, inform the user about the maximum load capacity and speed that the tire can safely handle. Understanding these ratings is vital for tire safety.

- DOT Code: This code indicates compliance with the Department of Transportation standards. It includes the plant code, tire type code, and the date of manufacture, offering transparency about the tire’s origins and tire construction specifics.

Together, these components contribute to the role of sidewall thickness in tire safety, ensuring the tire performs optimally under various conditions and stresses.

Must check: How Close to Sidewall Can a Tire Be Patched? Crucial Facts

How Thick is the Sidewall of a Tire

The thickness of tire sidewall varies based on tire type, vehicle, and driving conditions. For passenger cars, the average thickness for tire sidewalls ranges from 6 to 10 millimeters (0.24 to 0.40 inches), providing a balance between handling and comfort. Light trucks typically have sidewalls from 8 to 15 millimeters (0.32-0.60 inches), offering durability for heavier loads.

SUVs, with sidewalls between 10 to 18 millimeters (0.40-0.72 inches ), and trucks, ranging from 12 to 24 millimeters (0.48-0.96 inches), require thicker sidewalls for additional support and off-road resilience.

How thick the sidewall of a tire should be depends on several factors, including load and speed ratings, as well as the intended application. Performance tires have thinner sidewalls for better responsiveness, while comfort tires have thicker sidewalls for a smoother ride.

The ideal tire sidewall thickness varies depending on vehicle type and usage. Passenger cars typically have sidewalls of 6-10 mm, suitable for general driving. Light trucks often have 8-15 mm sidewalls for heavier loads. SUVs and off-road vehicles benefit from 10-18 mm sidewalls for rough terrain, while heavy-duty trucks may have sidewalls of 12-24 mm for demanding applications. Choosing the right sidewall thickness is crucial for optimal performance and safety.

| Vehicle Type | Recommended Tire Sidewall Thickness (mm) |

|---|---|

| Passenger Cars | 6-10 mm (0.24-0.40 inches) |

| Trucks and SUVs | 8-15 mm (0.32-0.60 inches) |

| Off-road Vehicles | 10-18 mm (0.40-0.72 inches) |

| Heavy-duty Vehicles | 15-20 mm (0.60-0.80 inches) |

In conclusion, tire sidewall thickness for different types of tires is a critical aspect to consider for vehicle safety and performance. Thicker sidewalls provide better support and durability, especially for heavy-duty and off-road vehicles, while thinner sidewalls enhance handling and fuel efficiency for passenger cars.

Must check: What is a Heat Ring on a Tire Sidewall and What Causes It?

Recommended Tire Sidewall Thickness

The recommended thickness of a tire’s sidewall varies based on vehicle type and usage, crucial for optimal performance and safety. Determining how thick the sidewall of a tire should be is essential, as it influences handling, comfort, and durability.

A thicker sidewall generally offers better shock absorption and is ideal for off-road or utility vehicles. In contrast, a thinner sidewall can enhance the handling and speed response for sports cars.

The impact of sidewall thickness on tire lifespan is significant. A properly chosen sidewall thickness can greatly extend a tire’s life, balancing the needs for performance and endurance against various driving conditions.

Typical Passenger Tire Sidewall Thickness

Most passenger vehicle tires have sidewalls between 6 to 15 millimeters (0.24 to 0.60 inches) thick on average. Sidewall thickness varies by tire type and size, playing a crucial role in the vehicle’s handling and ride comfort.

When considering what is the average thickness for tire sidewalls in passenger cars, it’s important to recognize that this range allows for a balance between flexibility and support. Thicker sidewalls in this range can offer better protection against potholes and rough surfaces, enhancing durability.

Here is a table of typical passenger tire sidewall thicknesses based on tire size:

| Tire Size | Sidewall Thickness |

|---|---|

| P195/65R15 | 6-8 mm (0.24-0.32 inches) |

| P215/65R16 | 7-9 mm (0.28-0.36 inches) |

| P225/60R17 | 8-10 mm (0.32-0.40 inches) |

| P235/55R18 | 9-11 mm (0.36-0.44 inches) |

| P245/45R19 | 10-12 mm (0.38-0.48 inches) |

Conversely, thinner sidewalls tend to provide sharper handling and response, crucial for performance-oriented vehicles. Ultimately, the optimal sidewall thickness for passenger cars depends on the intended use, be it everyday commuting or more spirited driving.

Truck and SUV Tire Sidewall Thickness

Truck and SUV tires require thicker sidewalls from 8 to 18 millimeters (0.32 to 0.72 inches). This increased thickness is essential for supporting the heavier weight of these vehicles and for providing durability under more demanding conditions, such as off-road driving.

When asking, how thick are tire sidewalls for trucks and SUVs, it’s evident that this range is designed to endure the additional strain and loads these vehicles encounter.

Here is a table of typical truck and SUV tire sidewall thicknesses based on tire size:

| Tire Size | Sidewall Thickness |

|---|---|

| LT235/70R16 | 8-10 mm (0.32-0.40 inches) |

| LT245/70R17 | 9-11 mm (0.36-0.44 inches) |

| LT265/70R18 | 10-12 mm (0.40-0.48 inches) |

| LT275/65R19 | 11-13 mm (0.44-0.52 inches) |

| LT285/60R20 | 12-14 mm (0.48-0.56 inches) |

Thicker sidewalls in trucks and SUVs not only contribute to better load-bearing capabilities but also offer improved resistance against off-road hazards like rocks and branches. This enhanced sidewall strength is key for maintaining tire integrity and performance in rugged environments, where durability and reliability are paramount.

Tire Sidewall Thickness Measurement

There are a few ways to measure tire sidewall thickness, each method providing crucial insights into tire health and suitability. The most common technique involves using specialized tools like calipers, which offer precise measurements.

In the context of measuring sidewall thickness in truck tires, such tools are indispensable due to the thicker sidewalls these vehicles typically have. Furthermore, how is tire sidewall thickness measured also depends on the tire’s condition and accessibility.

For an accurate measurement, the tire should be free of mud, dirt, or debris. This step is vital for maintaining tire performance and safety, particularly in vehicles carrying heavy loads where accurate sidewall thickness is crucial for overall stability.

Tire Sidewall Thickness Rating

Tire sidewall thickness is also indicated by load range ratings printed on the sidewall, a key aspect of tire specifications. This rating system, often overlooked, is essential for understanding how thick is the sidewall of a tire in relation to its intended use.

The load rating, which varies based on vehicle type, directly correlates with sidewall thickness. A higher load rating usually signifies a thicker sidewall, necessary for supporting heavier weights.

By decoding sidewall markings for thickness, drivers can ensure their tires are apt for their vehicle’s requirements. It’s not just about the physical measurement; the sidewall’s load rating gives a broader picture of the tire’s capabilities, impacting everything from handling to safety.

Must check: How to Tell if a New Tire is Defective: Ensure Your Safety

Why Tire Sidewall Thickness Matters?

The thickness of a tire’s sidewall plays a pivotal role in determining its durability, impact resistance, and overall performance. Understanding tire sidewall thickness and tire performance correlation is key to choosing the right tires. The how thick is the sidewall of a tire directly impacts how a tire behaves under various conditions, affecting everything from comfort to safety.

Whether it’s a rugged off-road tire or a sleek high-performance model, sidewall thickness is a critical factor that defines the tire’s character and capabilities. This element is not just a physical dimension; it’s a significant determinant of a tire’s functionality and suitability for specific applications.

Impact on Ride Comfort and Noise

Thicker tire sidewalls provide more absorption and flex for a smoother, quieter ride. This additional cushioning helps in dampening road noise and vibrations, contributing to a more comfortable driving experience. Especially in passenger vehicles, a thicker sidewall can significantly improve ride quality.

The increased thickness also aids in absorbing impacts from potholes and rough road surfaces. However, it’s important to balance this aspect with influence of sidewall thickness on fuel efficiency, as thicker sidewalls can increase rolling resistance, slightly affecting fuel economy. Choosing the how thick the sidewall of a tire should be involves a trade-off between comfort and efficiency.

Effect on Handling and Control

Thinner sidewalls generally yield better handling and control. They allow for more precise steering responses and improved cornering stability, making them ideal for sidewall thickness for high-performance sports tires. This reduced sidewall flex translates to a more direct road feel, essential for performance driving.

However, effects of low sidewall thickness in economy tires include a harsher ride and increased susceptibility to damage from road imperfections. Therefore, while thin sidewalls enhance driving dynamics, they require careful consideration regarding ride quality and durability, especially in everyday driving scenarios.

Importance for Durability and Wear

Thicker tire sidewalls better withstand curbing and impacts, resisting damage. This robustness is particularly important in tires subjected to harsh conditions, such as off-road or heavy-duty applications. The added thickness provides a buffer against external forces, reducing the likelihood of punctures or sidewall splits.

This attribute is vital for puncture resistance, ensuring the tire remains serviceable even in challenging environments. Moreover, repairing damaged tire sidewalls: thickness considerations come into play; thicker sidewalls might be more resilient to minor damages, potentially reducing the frequency of tire replacements due to sidewall-related issues.

Influence on Load Capacity

Thicker tire sidewalls allow higher inflation pressures, increasing load capacity. This feature is essential for vehicles that carry heavy loads, such as trucks and SUVs. The robust sidewall structure supports the weight more effectively, preventing the tire from deforming excessively under load.

This capability is crucial for maintaining stability and safety, especially when transporting goods or towing. The sidewall thickness plays a critical role in defining a tire’s load-bearing capacity, making it a key consideration in tire selection for utility vehicles or those used in commercial applications.

Role in Safety and Failure Resistance

Thicker sidewalls are less prone to impacts, slashes, and run-flat damage. This resilience is crucial in maintaining tire integrity in adverse conditions, thereby enhancing overall safety. Thicker sidewalls are better equipped to resist catastrophic failures, such as blowouts, especially at high speeds or under heavy loads.

This added safety margin is essential, particularly in high-stakes driving situations. Furthermore, in the event of air loss, thicker sidewalls in run-flat tires can support the vehicle for a limited distance, allowing safe travel to a repair facility. Thus, the sidewall’s thickness is a vital factor in ensuring a tire’s reliability and safety.

Must check: Do New Tires Come With Rims in Them? Know Before You Buy

Measuring Your Tire Sidewall Thickness

Measuring the sidewall thickness of your tire is a straightforward process that can provide valuable insights into tire condition and suitability. Knowing how to measure the thickness of a tire sidewall is crucial for maintaining tire health and performance. This process involves simple yet precise techniques that every vehicle owner should be familiar with.

Regularly checking the sidewall thickness measurement not only ensures your tire’s integrity but also offers a proactive approach to tire maintenance. This is particularly important for detecting early signs of wear or damage that could affect vehicle safety and performance.

Tools and Techniques for Measurement

Measuring the sidewall thickness of a tire involves specific tools and techniques to ensure accuracy. The most common tool used is a digital caliper, which offers precise and reliable measurements. The process starts with cleaning the tire surface to remove any dirt or debris.

Once clean, the caliper is positioned perpendicular to the sidewall to measure its thickness. It’s important to measure at several points around the tire to account for uneven wear.

Additionally, understanding the tire sidewall thickness involves recognizing the variations caused by different tire types and usage patterns. This measurement is an essential aspect of tire maintenance, as it directly impacts the tire’s performance and the vehicle’s handling characteristics.

Understanding Tire Size Markings

The markings on a tire’s sidewall provide essential information about its size, including its thickness. These markings include a series of numbers and letters that indicate the tire’s dimensions, load capacity, and speed rating. The aspect ratio, a part of these markings, indirectly suggests the sidewall thickness measurement.

A higher aspect ratio number usually means a taller sidewall. Understanding these markings is crucial in determining the importance of tire sidewall thickness for your specific vehicle.

This knowledge not only helps in selecting the right tires but also in assessing their suitability for various driving conditions. Therefore, decoding these sidewall markings is a key skill for any driver, ensuring their tires are well-suited for their vehicle’s needs and driving habits.

Must check: Can You Restud Studded Tires? Answering All Your Questions

Factors Influencing Tire Sidewall Thickness:

Various factors influence the sidewall thickness of a tire, each contributing to its performance characteristics and suitability for different vehicles. These factors range from the intended use and driving conditions to the manufacturing process.

Understanding how thick the sidewall of a tire should be depends on these variables, which collectively determine a tire’s ability to meet specific demands. This thickness is not arbitrary but is a calculated aspect of tire design, aimed at maximizing performance, safety, and durability.

Recognizing the factors affecting tire sidewall thickness is essential for making informed decisions about tire selection and maintenance.

Tire Size and Purpose

The size and intended purpose of a tire are key determinants of its sidewall thickness, affecting everything from handling to fuel efficiency. Larger tires designed for heavy-duty vehicles typically have thicker sidewalls for enhanced load-bearing capacity. Conversely, smaller tires for passenger cars might have thinner sidewalls to improve handling and reduce weight.

For instance, sidewall thickness standards for off-road tires are higher to withstand rugged terrain, whereas seasonal tires like those used in summer might have different sidewall specifications for optimal performance in warmer conditions. Thus, size and purpose significantly dictate the appropriate sidewall thickness.

Performance and Comfort Trade-offs

In tire design, there is often a trade-off between performance and comfort, with sidewall thickness being a critical factor in this balance. Thinner sidewalls typically offer better handling and responsiveness, favored in performance or sports cars.

On the other hand, thicker sidewalls provide better ride comfort by absorbing road irregularities, suitable for luxury or long-distance vehicles.

This trade-off is especially evident when comparing sidewall thickness in summer and winter tires, where each is designed for specific performance criteria under different seasonal conditions. Balancing these aspects is key in achieving the desired handling and comfort levels.

Climate and Road Conditions

Climate and road conditions significantly impact the required sidewall thickness, with different environments necessitating different tire characteristics. For instance, tires used in colder climates or on snow-covered roads might require thicker sidewalls for added durability and traction.

Similarly, tires for warmer climates might have a different thickness to cope with heat buildup. Road conditions, such as off-road or uneven surfaces, also play a crucial role, requiring tires with sidewalls robust enough to handle such challenges. Therefore, sidewall thickness must be aligned with environmental and road conditions to ensure optimal performance and safety.

Manufacturing Materials and Techniques

The materials and manufacturing techniques used in tire production play a crucial role in determining the final sidewall thickness and quality. Advances in material sciences have led to the development of new compounds that allow for varying sidewall thicknesses while maintaining strength and flexibility.

The manufacturing process, including the layering of materials and curing techniques, also significantly impacts sidewall thickness.

Regular tire sidewall thickness maintenance ensures that the tires remain in good condition, adhering to the prescribed standards. As manufacturing technologies evolve, so do the possibilities for optimizing sidewall thickness to meet specific driving needs.

Must check: Are Snow Tires Good in Mud? Unveiling the Truth

Choosing the Right Sidewall Thickness

Selecting the right sidewall thickness for your tires is a decision that impacts safety, performance, and durability. The process requires consideration of various factors tailored to your vehicle’s needs and driving conditions.

Understanding the ideal thickness of a tire sidewall for different driving conditions is crucial for optimal tire performance. This choice influences everything from handling and fuel efficiency to ride comfort and tire lifespan.

Making an informed decision on how to choose the right tire sidewall thickness for your needs ensures that your tires are well-suited to your driving habits and environment, enhancing both safety and the driving experience.

- Vehicle Type: Consider the manufacturer’s recommendation for sidewall thickness, particularly for passenger cars. Thicker sidewalls are preferable for trucks and SUVs for added durability under heavy loads.

- Driving Conditions: For regular road use, standard thickness is sufficient. Off-road driving demands thicker sidewalls for puncture resistance and stability.

- Wear Indicators: Select tires with wear indicators for timely maintenance. This aids in tips for extending the life of your tire sidewalls.

- Professional Guidance: Consult a mechanic or tire specialist. They can provide personalized advice on sidewall thickness based on your vehicle and driving style.

- Safety: Regularly inspect tire sidewalls for damages. Safety implications of using tires with damaged sidewalls are significant and should be addressed promptly.

- Performance Requirements: Adjust sidewall thickness based on your vehicle’s performance needs. Thicker sidewalls can support high-speed stability and durability.

- Budget and Longevity: Balance cost with the benefits of using tires with thick sidewalls. Thicker sidewalls often equate to longer tire life, making them a cost-effective choice in the long run.

Choosing the right sidewall thickness is about finding the perfect balance between these factors to meet your specific needs.

Must check: Top 10 Best Tire Siping Tools for Tires: Unbiased Reviews

Exploring Tire Sidewall Thickness: How Thick is the Sidewall of a Tire?

Explore the most common inquiries about tire sidewall thickness, as we delve into expert answers that clarify this vital aspect of tire knowledge. Understanding the role and impact of tire sidewall thickness on various aspects of vehicle performance and safety is crucial for every vehicle owner.

These frequently asked questions cover a range of topics, from handling performance to puncture resistance and towing capacity, offering insights into how sidewall thickness affects your driving experience.

Here, we address these queries, providing concise yet comprehensive answers to help you make informed decisions about your tires:

How thick should a tire sidewall be?

The ideal tire sidewall thickness depends on vehicle type, usage, and driving conditions. For passenger cars, 6-10 mm is typical, while SUVs and trucks might need 8-15 mm. It’s crucial to balance sidewall thickness with safety needs and performance expectations. Consult your vehicle’s manual or a tire professional for specific recommendations based on your vehicle model and driving habits.

Do thicker tire sidewalls improve handling?

Thicker sidewalls don’t necessarily improve handling; they can actually reduce handling sharpness due to increased flex. However, they do provide better resistance against impacts and road imperfections. For sharper handling, a balanced sidewall thickness that aligns with the vehicle’s design and usage pattern is recommended.

How does tire sidewall thickness affect handling?

Tire sidewall thickness influences handling performance by affecting the tire’s responsiveness. Thinner sidewalls typically offer better handling due to reduced flex, enhancing the vehicle’s response to steering inputs. Conversely, thicker sidewalls can lead to a less responsive handling experience.

Can thicker sidewalls prevent punctures?

Yes, increased tire sidewall thickness can enhance puncture resistance. Thicker sidewalls are more robust, providing better protection against sharp objects and rough terrains. This makes them ideal for off-road or rugged driving conditions where the risk of punctures is higher.

What’s too thick or thin for a tire sidewall?

The optimal thickness for a tire sidewall varies by vehicle and usage. Too thick can reduce handling and increase fuel consumption, while too thin may compromise durability and puncture resistance. It’s important to align sidewall thickness with your vehicle’s specifications and your driving needs.

How does tire sidewall thickness affect ride quality?

Tire sidewall thickness significantly impacts ride comfort. Thicker sidewalls generally provide a smoother ride by absorbing road irregularities more effectively. They cushion the vehicle against bumps and potholes, enhancing comfort. However, they might also reduce the vehicle’s responsiveness.

Do I need thick sidewalls for towing?

For towing, thicker sidewalls are recommended as they offer better towing capacity and stability. They can handle the additional stress and weight, providing safer and more stable towing experiences. Check your vehicle’s towing specifications for the appropriate sidewall thickness.

What is the recommended sidewall thickness for trucks?

For trucks, a tire sidewall thickness ranging from 8 to 15 mm is generally recommended. This range supports the truck tires under heavier loads and more demanding driving conditions, offering better durability and load-bearing capacity.

How does tire sidewall thickness affect noise reduction?

Thicker sidewalls can contribute to lower noise levels inside the vehicle. They absorb vibrations and road noise more effectively, leading to a quieter ride. However, the tire’s tread pattern and rubber composition also play significant roles in noise reduction.

Wrapping Up: How Thick is the Sidewall of a Tire in Different Vehicle Types

To sum up, the thickness of a tire’s sidewall is a key factor in vehicle safety and performance, essential for informed tire choices and optimal driving experiences. Grasping how thick is the sidewall of a tire and how thick are tires overall is crucial for your vehicle’s handling and durability.

The thickness of a tire sidewall typically ranges between 0.24 to 0.60 inches (6 to 15 millimeters), affecting tire sidewall thickness safety and responsiveness. The thickness varies based on tire type, vehicle, and driving needs. Passenger car tires usually have sidewalls between 0.24 to 0.40 inches (6 to 10 mm), light truck tires between 0.32 to 0.60 inches (8 to 15 mm), SUV tires from 0.40 to 0.72 inches (10 to 18 mm), and truck tires from 0.48 to 0.96 inches (12 to 24 mm).

Performance tires often have thinner sidewalls for better handling, while comfort tires have thicker sidewalls for a smoother ride. This aspect significantly influences the impact of sidewall thickness on tire lifespan, ensuring that the right choice can lead to enhanced tire longevity and reliability.

Ultimately, the importance of using the correct tire sidewall thickness for your vehicle is paramount. It’s not just about meeting manufacturer standards; it’s about optimizing your vehicle’s performance and safety, tailored to your specific driving requirements. This understanding is vital for any driver seeking a balanced and secure driving experience.

You might want to explore: