Ever wondered how thick is a tire below the tread? Did you know that the thickness of a tire below the tread can significantly impact its performance and safety? It’s a lesser-known fact that the tire thickness below the tread is a critical factor that you should be aware of. Understanding the depth of a tire below the tread is essential for maintaining proper traction, stability, and overall tire integrity.

When it comes to measuring tire thickness below tread, there are various factors to consider, including the construction of the tire, different tire types, and the overall wear and tear.

In this guide, we will look into the layers and components of a tire and explore how thickness below the tread affects tire performance and safety. We will also discuss how to measure tire thickness below the tread and provide important insights into maintaining the proper thickness for optimal tire performance.

Key Takeaways:

- The thickness of tire below tread directly impacts tire performance and safety.

- Different tire types and constructions can result in variations in tire thickness below tread.

- Measuring tire thickness below the tread is crucial for maintaining optimal traction and stability.

- Proper thickness of tire layers below tread is essential for preventing tire wear and ensuring a longer lifespan.

- Consulting tire manufacturer specifications and seeking professional inspection is recommended for accurate measurements and assessment of tire thickness.

What Lies Beneath the Tread? Understanding the Structure of a Tire

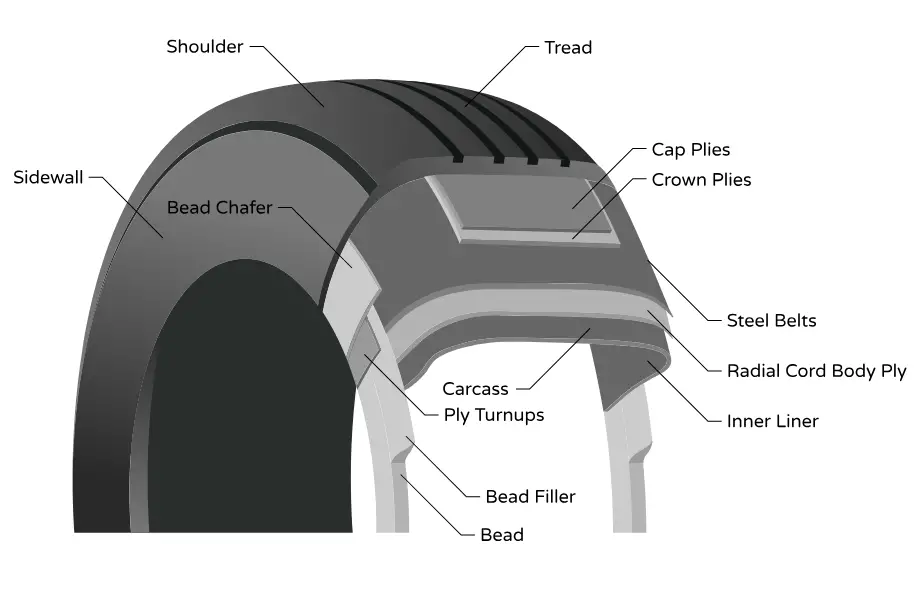

Before delving into the thickness below the tread, it’s important to have a clear understanding of the structure of a tire. A tire consists of various components, each with its own unique function.

- The Tread: The tread is the part of the tire that makes contact with the road and provides traction. It is designed with patterns and grooves to enhance grip and channel water away.

- Sidewalls: The sidewalls of the tire provide support and protection. They are the vertical sections of the tire that connect the tread to the bead, maintaining tire shape and resisting external forces.

- Carcass Plies: The carcass plies are layers of fabric, typically made of polyester or nylon, that provide strength and stability to the tire. These plies are located beneath the tread and extend to the sidewalls.

- Steel Belts: The steel belts are reinforcement layers located beneath the tread. They are made of tightly wound steel wires and help maintain tire shape, improve stability, and resist punctures.

- Beads: The beads are the parts of the tire that secure it onto the rim. They are made of steel wire bundles coated in rubber and provide a firm grip onto the rim, preventing tire slippage.

- Inner Liner: The inner liner is a layer of rubber located inside the tire. It acts as a barrier to prevent air leakage, maintaining tire pressure, and enhancing safety.

Knowing about each of these tire components is essential in comprehending how the thickness of tire below tread is determined. The interaction and integration of these components contribute to the overall performance, durability, and safety of the tire.

Must check: How Thick is the Sidewall of a Tire and Why It Matters

Why Understanding Tire Thickness Below the Tread Matters

Understanding the tire thickness below tread is crucial as it can have a significant impact on tire performance, safety, and lifespan. The tire thickness below the tread can affect factors such as handling, durability, and fuel efficiency. A tire with an insufficient thickness may compromise its ability to provide adequate traction and stability, potentially leading to accidents or poor performance.

Additionally, a worn-out or damaged tire with reduced thickness beneath tire tread may be more prone to blowouts or other tire failures. It’s important for us to be aware of the thickness of tire layers below tread to ensure we are using tires that are safe and in optimal condition.

Impact on Tire Performance

The thickness of tire under tread can significantly affect tire performance. A tire with an appropriate thickness provides better handling, stability, and traction, which are essential for safe and efficient driving.

Thicker tires offer improved stability on the road, reducing the risk of skidding or losing control, especially in wet or slippery conditions. Adequate thickness also enhances the tire’s ability to maintain proper contact with the road surface, maximizing traction and improving overall performance.

Enhanced Tire Safety

Proper tire thickness plays a vital role in ensuring driver safety. An insufficient thickness of tire under tread can lead to reduced grip and compromised handling, increasing the risk of accidents.

Thicker tires provide better resistance to punctures and damage, enhancing overall safety on the road. Additionally, thicker tread depth helps with water dispersion, reducing the chances of hydroplaning on wet surfaces, further improving safety.

Extended Tire Lifespan

The tire thickness below the tread is closely linked to the lifespan of a tire. Thicker tires generally have a longer lifespan as they have more rubber material to wear down over time. Adequate thickness allows the tire to withstand wear and tear, increasing its durability and longevity.

Furthermore, maintaining proper thickness can help prevent premature tire aging, reducing the risk of sidewall cracking and other structural damages that can shorten tire lifespan.

By understanding and considering the importance of the thickness beneath tire tread, you can make informed choices when it comes to tire selection, maintenance, and replacement. Prioritizing tire safety and performance ensures a smoother and safer driving experience, while also maximizing the lifespan of the tires.

How Thick is a Tire Below the Tread?

When it comes to the thickness of a tire below the tread, several factors come into play. The tire type, size, and construction can all influence this measurement. While the precise measurement may vary, on average, the tire thickness below the tread can range from 2-5 millimeters. It’s important to note that this measurement can differ based on the specific tire and its intended use.

The thickness of a tire below the tread varies depending on the tire size and type, but typically ranges from 2 to 5 millimeters (0.08 to 0.2 inches). This hidden layer, also known as the body plies, is composed of steel belts and other reinforcing materials that provide structural integrity, impact resistance, and contribute to the overall lifespan of the tire.

Different tire types, such as passenger car tires, SUV/truck tires, and off-road tires, may exhibit variations in thickness of tire layers below tread. To obtain precise measurements for a particular tire, it is crucial for you to consult the specifications provided by the tire manufacturer.

These specifications will provide accurate information about the tire’s thickness below the tread for a specific tire model. By learning the exact measurement, you can make informed decisions about tire maintenance and replacement, ensuring optimal performance and safety on the road.

Knowing the thickness of tire under tread is essential for understanding tire integrity and performance. Adequate thickness ensures proper traction, stability, and overall tire function. It is important for you to regularly monitor and maintain the appropriate tire thickness, as worn-out or damaged tires with reduced thickness can pose safety risks.

By prioritizing tire thickness measurement and maintenance, you can enjoy enhanced performance and peace of mind while on the road.

You might also like: What is the Minimum Tread Depth for Front Tires? Essential Facts

Factors Affecting the Tire Thickness Below the Tread

When it comes to the thickness of tire under tread, several factors come into play, including the type of tire, speed rating, and load rating. These factors contribute to variations in tire construction and ultimately impact the thickness of tire layers below tread. Let’s explore each factor in more detail:

Tire Type

Passenger car tires, SUV/truck tires, and off-road tires differ in their construction and thickness. Each tire type is designed to meet specific performance requirements based on the intended vehicle and usage.

Passenger car tires, commonly used for everyday driving, have a different tire thickness below the tread compared to more rugged SUV/truck tires or off-road tires designed for challenging terrains.

Speed Rating

Tires designed for higher speed ratings often require additional reinforcement layers to withstand the increased forces and temperatures generated at higher speeds. These reinforcement layers can impact the overall thickness of tire layers below tread.

Higher speed ratings, such as those found in performance tires, demand a slightly different tire construction to ensure durability and safety, resulting in variations in thickness.

Load Rating

Tires designed for heavier loads, such as those used in commercial vehicles or towing applications, require extra reinforcement to handle the additional weight. These additional reinforcement layers can impact the total thickness below the tread.

A higher load rating necessitates a stronger tire construction with added layers, influencing the overall thickness of the tire below the tread.

By considering tire type, speed rating, and load rating, you can make informed decisions about tire selection and better understand the thickness below the tread for your specific tires. Monitoring and maintaining proper thickness are essential for optimizing tire performance and ensuring safety on the road.

Thickness Variations in Different Tire Parts

The tire thickness below the tread can vary in different parts of the tire. Understanding these variations can provide further insight into the overall tire structure and performance.

The tread thickness directly affects traction and wear rate, determining the tire’s ability to grip the road surface and withstand the rigors of daily use.

The sidewall thickness plays a crucial role in handling and protection. It provides structural support, allowing the tire to maintain its shape and endure external forces encountered during driving.

The carcass thickness, which includes the plies and rubber layers, contributes to the strength and rigidity of the tire. It provides the structural foundation and flexibility necessary for optimal tire performance.

The steel belt thickness is responsible for reinforcing the tread area, enhancing tire stability, and resisting punctures. Its thickness can affect the tire’s ability to maintain its shape and deliver reliable performance.

The inner liner thickness serves as a barrier for air retention, preventing rapid pressure loss. It helps maintain proper tire inflation and reduces the risk of tire-related accidents.

Exploring these variations in tire thickness allows you to better understand the inner workings and intricacies of your tires, enabling informed decisions and optimal tire care.

The Crucial Layer: Examining the Carcass Thickness

The carcass is a crucial layer in the tire structure and plays a significant role in its overall strength and integrity. Understanding the importance of the carcass thickness is essential for you to make informed decisions regarding tire selection and maintenance.

The carcass can be constructed with various materials, such as nylon, polyester, or steel, each with its own characteristics and performance benefits. These materials are carefully chosen to provide the necessary strength and durability for different tire types and sizes.

Depending on the tire type and size, there can be variations in the carcass thickness. Passenger car tires, truck tires, and off-road tires may have different carcass thicknesses to accommodate their specific usage requirements.

The Supporting System: Understanding Steel Belting Thickness

Steel belts play a crucial role in maintaining the shape and stability of a tire. These belts are typically located beneath the tread and provide reinforcement to prevent tread distortion and enhance tire performance.

The thickness of the steel belts can vary depending on the tire type and size. Certain tires may have multiple steel belts, while others may have a single belt. Variations in individual belt thickness can also impact tire performance.

It’s important for you to understand the significance of steel belting thickness in ensuring tire stability and performance.

The Sidewall Barrier: Examining Sidewall Rubber Thickness

When it comes to tire construction, the sidewall plays a crucial role in protecting the tire and maintaining handling characteristics. The sidewall acts as a barrier between the road and the inner layers of the tire, providing essential support and safeguarding against external damage. Sidewall rubber thickness is an important consideration that directly impacts tire performance and safety.

The sidewall rubber thickness can vary compared to other tire sections, such as the tread or carcass. While the tread is responsible for traction and the carcass provides strength and rigidity, the sidewall adds an additional layer of protection. The typical thickness of sidewall rubber depends on various factors, including tire size and application.

Factors influencing sidewall thickness include:

- Tire size: Larger tires commonly have thicker sidewalls to accommodate the increased load and offer enhanced protection.

- Tire application: Specialized tires designed for off-road or high-performance use may have thicker sidewalls to withstand rugged terrains or provide better cornering stability.

It’s important for you to consider these factors when evaluating sidewall thickness for your specific tires. Adequate sidewall thickness ensures optimal tire performance and reduces the risk of sidewall damage due to impacts, debris, or prolonged wear and tear.

Must check: How Many Miles is a 600 Treadwear Rating? A Detailed Analysis

What is the Minimum Safe Thickness for the Tire Below the Tread?

The minimum safe thickness for the tire below the tread is an important consideration for maintaining safety on the road. While the exact measurement may vary depending on jurisdiction, there are general guidelines and safety requirements in place.

It is commonly recommended to have a minimum tire tread depth of 2/32 of an inch (approximately 1.6 millimeters) for safe driving. However, it’s essential to consult local regulations and manufacturer guidelines for specific requirements. Regularly monitoring and maintaining proper tire thickness are crucial for safe driving and optimal tire performance.

| Tire Thickness | Safety Requirements |

|---|---|

| 2/32 of an inch (1.6 millimeters) | Common recommendation for minimum tire tread depth |

| Varies | Consult local regulations and manufacturer guidelines |

Differentiate Between Tread Depth and Under-Tread Thickness

Tread depth and under-tread thickness are two important measurements when it comes to assessing tire condition and performance. However, these terms have distinct meanings and shouldn’t be confused with each other.

Tread depth refers to the measurement of the rubber material on the outer surface of the tire. It is typically measured in millimeters or inches and directly impacts traction and wear rate. The tread depth plays a crucial role in ensuring adequate grip on the road, especially in wet or slippery conditions.

Under-tread thickness, on the other hand, refers to the thickness of the tire below the tread. It includes various layers and components such as the carcass, steel belts, and inner liner. The under-tread thickness contributes to the overall structure, strength, and integrity of the tire.

It’s important to understand the difference between tread depth and under-tread thickness to accurately assess tire condition and performance. While tread depth focuses on the outer surface of the tire, under-tread thickness delves deeper into the layers and components that make up the tire’s structure.

How to Measure Tire Thickness Below the Tread

Measuring the thickness of tire below tread is a vital aspect of tire maintenance that ensures optimal performance and safety. One effective tool for this task is a tire depth gauge. The tire depth gauge allows for accurate measurement of the tread depth, enabling you to determine if your tires meet the minimum safe thickness requirements.

Using a tire depth gauge is simple and straightforward. Follow these step-by-step instructions to measure the tire thickness below tread at home:

- Ensure your vehicle is parked on a level surface and the tires are cool to the touch.

- Select a tire depth gauge suitable for your tire type.

- Insert the measuring rod of the tire depth gauge into the tread groove, making sure it is perpendicular to the tire’s surface.

- Press the tire depth gauge down firmly until the base of the measuring rod rests on the tire’s tread blocks.

- Read the measurement value displayed on the tire depth gauge. This value represents the tire thickness below tread.

- Repeat the process at multiple points across the tire’s surface, including the center and both sides, to ensure accurate and consistent measurements.

- Record the measurements and compare them to the minimum safe tire thickness requirements.

It is worth noting that there are alternative methods for measuring tread depth, such as the penny test. This involves inserting a penny into the tread groove with Lincoln’s head facing downward. If the top of Lincoln’s head is visible, it indicates that the tire tread depth is below the recommended threshold, suggesting the need for replacement.

Measuring tire thickness below the tread is a crucial part of tire maintenance that helps ensure optimal performance, handling, and safety. By using a tire depth gauge or alternative methods like the penny test, you can confidently monitor tire tread depth and take appropriate action when necessary.

Difficulties in Measuring Under-Tread Thickness

When it comes to measuring under-tread thickness, directly accessing the precise measurement can be quite challenging. There are inherent limitations and complexities involved in this task, making it impractical for regular measurement.

One of the main difficulties lies in accessing the thickness underneath the tread accurately. The tread, which is the part of the tire in direct contact with the road, can make it difficult to access the layers underneath for measurement.

Additionally, the construction of the tire and the presence of various layers further complicate the direct measurement process. These layers include the carcass plies, steel belts, and other components that contribute to the overall tire structure.

Given these challenges, it is advisable for you to consult the tire manufacturer’s specifications for general information on under-tread thickness. The manufacturer’s specifications provide valuable insights into the expected thickness of the tire below the tread, considering its specific design and intended use.

These specifications can serve as a reliable point of reference for understanding the expected thickness and ensuring compliance with safety standards. However, to obtain a more accurate assessment and address any concerns regarding under-tread thickness and overall tire safety, it is important to seek professional inspection.

Tire technicians, equipped with specialized knowledge and tools, can provide professional inspection services to accurately assess the thickness below the tread and identify any potential issues.

Professional inspections offer a comprehensive evaluation of the tire’s condition and can provide crucial recommendations for maintaining tire performance and safety.

How Thickness Affects Tire Performance

Variations in tire thickness can have a significant impact on various aspects of tire performance, including handling, durability, and fuel efficiency. Thicker tires tend to provide better stability and traction, resulting in improved handling on the road. The additional thickness in the tire contributes to enhanced grip, allowing the tire to better grip the road surface and maintain control during maneuvers.

Furthermore, thicker tires are often more durable and have a longer lifespan. The increased thickness provides extra rubber material, which helps to resist wear and tear. Thicker tires are less likely to wear down quickly, allowing them to maintain their performance characteristics over an extended period.

However, it’s important to note that while thicker tires offer benefits in terms of stability and durability, they may impact fuel efficiency. Thicker tires can increase rolling resistance, requiring more energy to move the vehicle forward. As a result, fuel efficiency can be slightly reduced when compared to thinner tires.

When considering tire performance, it’s crucial to examine the influence of specific tire components such as the carcass and belts. The thickness of the tire carcass, which includes the plies and rubber layers, plays a significant role in enhancing tire performance.

A thicker carcass provides added strength and rigidity to the tire, leading to better handling and stability. Similarly, the thickness of steel belts, which reinforce the tread area, contributes to tire stability and performance.

Overall, choosing the right tire thickness is important for optimizing tire performance. It’s essential to strike a balance between thickness and performance factors, such as handling, durability, and fuel efficiency, based on individual driving needs and preferences.

The Importance of Maintaining Proper Thickness

Proper tire thickness maintenance is crucial for ensuring tire integrity and safety. The thickness of a tire plays a significant role in its performance, providing the necessary traction and stability on the road. When tires become worn-out or damaged, their thickness below the tread can be reduced, leading to various risks and compromising safety.

Risks of Worn-Out Tires:

- Reduced Traction: Worn-out tires with decreased thickness below the tread have less grip on the road surface, resulting in reduced traction. This can lead to longer braking distances and an increased risk of skidding or sliding, especially in wet or slippery conditions.

- Poor Handling: As the tire tread wears down and its thickness decreases, the handling of the vehicle can be negatively affected. Steering responsiveness and stability may be compromised, leading to an increased risk of loss of control while driving.

- Inefficient Water Dispersion: Tires with worn-out tread and reduced thickness below the tread are less effective at dispersing water from the road surface, increasing the risk of hydroplaning. Hydroplaning occurs when a layer of water builds up between the tires and the road, causing the vehicle to lose contact with the road surface.

Risks of Damaged Tires:

- Reduced Structural Integrity: If a tire sustains damage, such as cuts, punctures, or bulges, its structural integrity can be compromised. This can lead to a decrease in the thickness beneath tire tread, posing a risk of tire failure, including blowouts or sudden loss of pressure.

- Uneven Wear: Damaged tires may experience uneven wear, with certain areas of the tire wearing down more quickly than others. This can result in an imbalance in tire thickness, affecting the overall performance and safety of the tire.

- Inadequate Load-Bearing Capacity: Tires with reduced thickness below the tread due to damage may have a reduced load-bearing capacity. This means they may be less able to support the weight of the vehicle and its occupants, potentially leading to tire overloading and increased risk of tire failure.

It is essential for you to prioritize tire thickness maintenance to mitigate these risks and ensure optimal safety on the road. Regularly inspecting tires for signs of wear, such as tread depth and any visible damage, is important. When the thickness of tire layers below tread becomes inadequate, it is recommended to replace the tires to restore safety and performance.

By maintaining proper tire thickness, you can enhance your safety and the longevity of your tires, reducing the risk of accidents and improving overall driving experience.

You might also like: Why Do I Keep Getting Nails in My Tires? (It’s Not Just Bad Luck!)

FAQs About Minimum Safe Thickness for Tire Below Tread:

Understanding the importance of tire thickness below tread pattern is essential for every vehicle owner. While most people are familiar with checking the tread depth of their tires, many are unaware of the significance of measuring the thickness of tire under tread.

Let’s check out some of the most frequently asked questions about the thickness of tire layers below the tread pattern and its impact your ride’s safety and performance. Here we go:

Is a thicker tire below the tread always better?

A thicker tire below the tread is not necessarily always better. While a thicker tire can provide added durability and stability, it may also increase rolling resistance and impact fuel efficiency. It’s important to strike a balance between tire thickness and performance based on individual driving needs and preferences.

How much thicker is a tire below the tread compared to the tread itself?

The thickness of a tire below the tread can vary depending on factors such as tire type, size, and construction. On average, the thickness below the tread can range from 2-5 millimeters. However, it’s crucial to consult tire manufacturer specifications for precise measurements tailored to specific tire models.

Can I measure the thickness of the tire below the tread myself?

Measuring the thickness of the tire below the tread directly can be challenging without specialized equipment. It is recommended to consult tire manufacturer specifications or seek professional inspection, such as from tire technicians, for accurate assessments of tire thickness.

Can a puncture damage the layers below the tread?

A puncture can potentially damage the layers below the tread, including the carcass and steel belts. If the puncture is severe enough, it may compromise the structural integrity of the tire and require immediate repair or replacement. It’s important to inspect tires regularly for punctures and address any damage promptly.

Can a damaged area below the tread be repaired?

The repair of a damaged area below the tread depends on the extent and nature of the damage. Minor damages, such as small cuts or punctures, can often be repaired by a professional using proper techniques and materials. However, significant or structural damages may require tire replacement. It is recommended to consult a tire expert for a proper assessment and recommendation.

Is it safe to drive with a damaged under-tread?

Driving with a damaged under-tread is not recommended as it can compromise tire performance and safety. A damaged under-tread may weaken the tire structure, increasing the risk of blowouts, loss of control, or reduced traction. It is advisable to have tires inspected by a professional and replace any damaged tires promptly.

Should I replace my tires based on the thickness below the tread?

Tire replacement should be based on overall tire condition, including the thickness below the tread, tread wear, and other factors such as age and signs of damage. If the thickness of tire layers below tread falls below the recommended minimum safe thickness for tire below tread, it may be an indication that the tire has reached the end of its lifespan and should be replaced.

Are there any warning signs that indicate thinning of tires below the tread?

There are several warning signs that may indicate thinning of tires below the tread. These can include visible bulges, cracks, or uneven wear patterns on the tire sidewalls or tread. Additionally, if the depth of the tire tread wears down significantly faster than expected, it may indicate potential thinning below the tread. It’s important to regularly inspect tires for these warning signs and address any concerns promptly.

Final Thought on How Thick are Tires Below the Tread

Maintaining the minimum safe thickness for the tire below the tread is of utmost importance to ensure safety while driving. Adequate tire thickness is vital for providing the necessary traction, stability, and performance on the road. It is crucial for you to regularly monitor tire thickness and adhere to the specified minimum safe thickness guidelines.

We hope know you know the answer to your question; how thick is a tire below the tread for vehicle safety?

The thickness of a tire below the tread varies depending on the tire size and type, but generally ranges from 2 to 5 millimeters (0.08 to 0.2 inches). This hidden layer, also known as the body plies, is composed of several layers of steel or fabric cords embedded in rubber, providing the tire with strength, stability, and support.

By prioritizing proper tire thickness, you can enjoy optimal tire performance and overall vehicle safety. Keeping tires within the recommended thickness range helps to minimize the risk of accidents, blowouts, and other tire failures. Additionally, maintaining adequate tire thickness contributes to the longevity of the tires, reducing the frequency of replacements and saving costs for you.

As responsible vehicle owners, it is our duty to prioritize the maintenance of proper tire thickness. Regular inspections, consultations with tire manufacturers, and seeking professional advice are essential steps towards ensuring the safety and performance of our tires.

By keeping an eye on tire thickness and taking prompt action when needed, we can drive with confidence, knowing that we are doing our part to protect ourselves and other road users.

You’ll likely appreciate diving into: